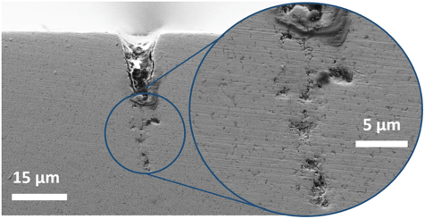

The use of fracture mechanics for rationalizing the fracture behavior of cemented carbides is valid, as far as sharp cracks, free of residual stresses and subjected to a well-defined stress state are used for assessing fracture toughness. However, machining a very sharp notch on the surface of hardmetals for fracture toughness testing has been a critical issue during many years. Within this context, introduction of surface “through-thickness” _micronotches (SEμVNB) by means of ultrashort pulsed laser ablation (UPLA) is here proposed, implemented and analyzed as an innovative precracking-like route within flexural testing procedures for appropiated evaluation of fracture toughness of cemented carbides. UPLA parameters used for introducing the micronotch are optimized in terms of induced damage ahead of the notch tip. For comparison purposes, fracture toughness is also determined by means of flexural testing of previously cracked single-edge notch beams (SENB-Cracked) as well as specimens with V-notch tips sharpened through diamond polishing using a razor blade, and Palmqvist indentation microfracture method. The satisfactory agreement found between values measured using UPLA-micronotched and SENB-Cracked (reference) specimens allows to conclude that flexural testing of SEμVNB samples is a valid methodology for reliable determination of fracture toughness of hardmetals. This is feasible because of the extremely short time of laser-matter interaction. It yields small and somehow controlled damage in front of the notch tip as a result of shock wave propagation during ablation, which translates into effective precracking of SEμVNB specimens

More information at:

Leave a Reply